OFFSHORE

Flowlines & Jumpers

FPS delivers flexible flowline and jumper systems engineered for the toughest offshore conditions. Designed for rapid installation, long service life, and total corrosion immunity, our offshore products perform in environments where steel systems fatigue, corrode, and fail.

Performance Characteristics

Designed for dynamic offshore conditions including vessel motion and subsea currents

Maintains flexibility under pressure and temperature cycling

Resistant to corrosion, fatigue, and internal scaling

Rated for high-pressure multiphase fluids, CO₂, and sour service environments

Applications

Subsea production tie-ins and manifold connections

Flowlines linking subsea wells, templates, and riser bases

Short-distance jumper systems for flow distribution or gas lift

Surface or mid-water flowlines in shallow and deep-water fields

Chemical injection, water injection, and multiphase transport lines

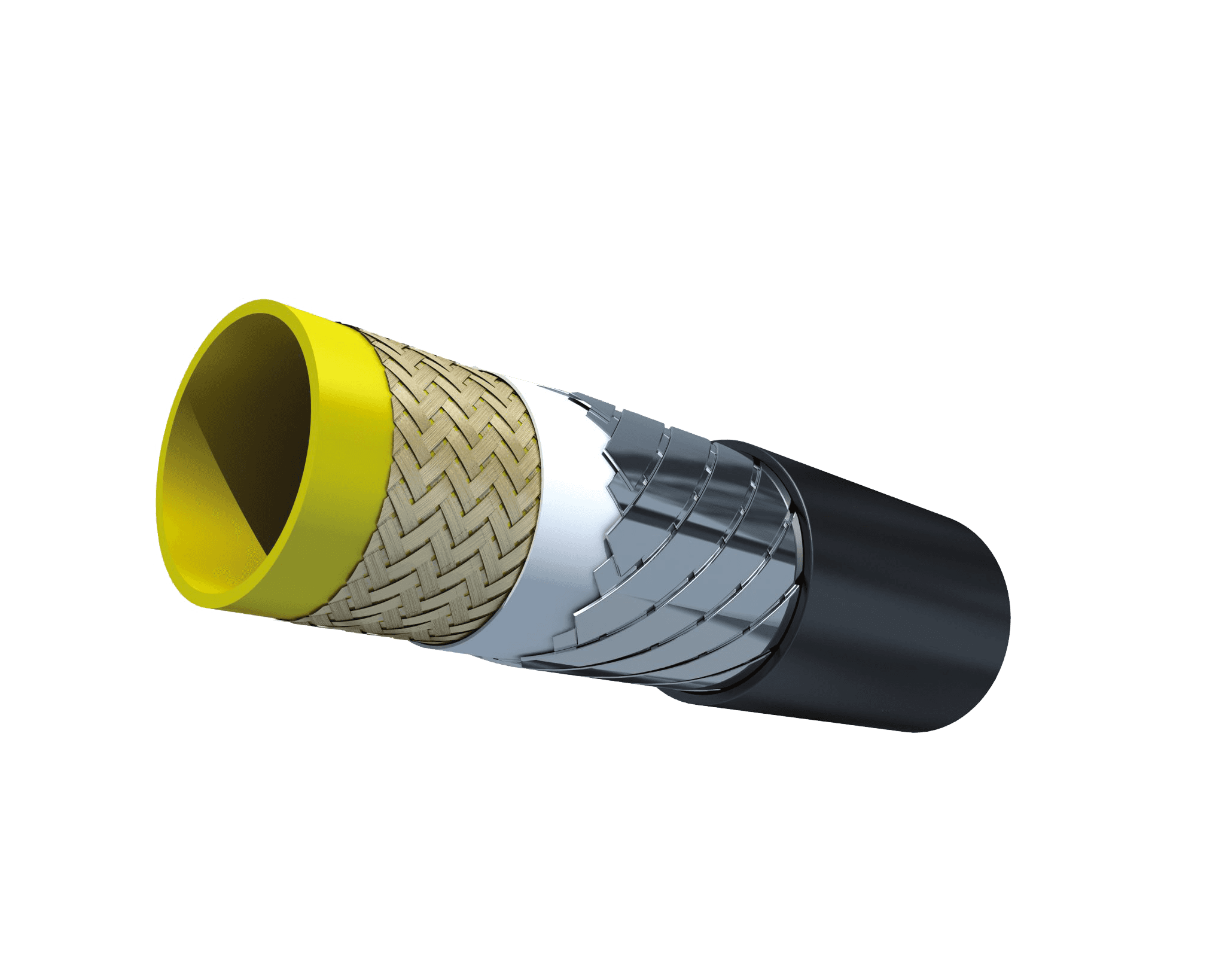

Structure and Material Options

Thermoplastic liners available in HDPE, PA-12, PEX, and PVDF for full chemical compatibility

Reinforcement layers in steel tape, aramid fiber, or composite cord for high-pressure strength

Outer protective sheathing engineered for abrasion and seawater resistance

Installation and Lifecycle Advantages

Deployable from plant directly to vessel for large carousel loads

Reduced mobilization and laydown time compared to welded steel systems

No welding, coating, or cathodic protection required

Compatible with horizontal and vertical connection systems

Simplified maintenance and low total cost of ownership

For more information see the brochure or contact us

File Size: 3MB